Do you cut off both ends of your shafts?

Equipment

I'm about to cut and fletch a dozen Black Eagle Carnivore shafts, and I've always cut both ends, because I've been told that most of the run out on shafts is at the ends. Is this really necessary, because it's a big pain in the ass?

I don't know that it is super critical but I always do it. I shoot longer arrows due to my draw length so I take the time to do it.

I never really considered it too big of a deal. The cutting is quick but squaring takes a little longer.

How big a pain can it be?

But, yes, I always cut an inch off the nock end and square.

If you had an arrow straightener you would see where the run out is but those things went away with alum arrows.

In my case I only need to cut off 1.5-2" from a full length shaft to get my arrow length. I only cut one end. I realize theoretically one "might" remove the runout by cutting both ends, but also wonder if the act of cutting the nock end and not getting it perfectly factory square offsets any potential benefit...

It's a big pain, because you have to cut and square two ends. Basically double the time and effort.

I do mine in a lathe with a cut off wheel, so cut and square in one operation. I guess I’m either spoiled or have way more time. Even so, how long does it take per dozen shafts?

Cutting both ends definitely helps to straighten graphite shaft. I have verified this with the techies at Gold Tip. When done properly, a .006 shaft can be straightened to a .003. Likewise a .003 can be straighten to a .001.

Properly cut and cut arrow shaft cost and improve shaft straightness which impacts arrow accuracy and performance.

Yes, I cut and square both ends

OK, both ends it is. Thanks for the input.

I shoot full length shafts but I do square both ends

OP, I'm guessing you are using a cutter like the pick above? If so, I highly recommend getting a professional quality electric cutter. They cut and square at the same time in one easy 2 second step. No need for a squaring tool.

Matt

Yea I got both ends. Square both ends. I spin Broadheads and see if any wobble and square until there is no wobble. IThen find the spine on my spine tester and fletch stiff side up

I use an electric cutoff saw, but it doesn't leave perfectly square ends.

Rod,

One like this, or several other similar models. If you roll the shaft while cutting, instead of just pushing it thru the blade, it will square the cut every time, in my experience.

Matt

I run my carbon arrow shafts over my old aluminum arrow straightener w/dial indicator as referenced by WapitiBob above. I mark the crooked ends I want to cut off....if one end is straight I do not cut it. Often I cut unequal amounts from both ends.

More important I believe is putting the nock on (into) the straightest end of the shaft. This leads to mismatched location and direction of the printed lettering on the arrows I don't care, they shoot best that way. That was a trick I learned on a 1000 wood shafts about 45 years ago and it is still valid today as per putting the nock on the straightest end.

I cut and square carbon shafts on my 10" Delta cabinet saw with a 90 tooth blade. Works very well once you get the technique down, and it has a dust collector on it.

The doctor cut off the front end of my shaft a few days after I was born. I've left the "nock" end alone..

That made me laugh out loud!

How can you tell which is the straightest end of the arrow? I ask because i've never heard that before. If i buy arrows from an archery shop, should i ask them to cut both ends and identify the straightest end? I dont feel confident i could do it at this point.. Thanks

Here’s my process.

I float them and find the stiff side. Mark it with a sharpie.

Spin them and find the wobble. If one side wobbles a lot, cut all from that end. If it’s equal then cut both ends.

Square each side and use a q tip with acetone to clean the inside of each end.

Not on ACCs otherwise on my all carbon shafts ...some times, unless they have bushings installed. I have not problems getting shafts to spin perfectly. I also only but good shafts. I dont cut any corners in my builds

How many thousandths is a “wobble ?”

The guy in the video, did not square his shafts, what is up with that?

I've only ever cut one end

Finally, I know why my shooting hasn't improved!!

I've always cut both ends. Of course I also index all my shafts with a Ram arrow spine tester. Cutting both ends is only the beginning of a potentially deep rabbit hole.

I have nine months between seasons so finding time to cut both ends is possible

I cut and square both ends.

How do you all square your ends?

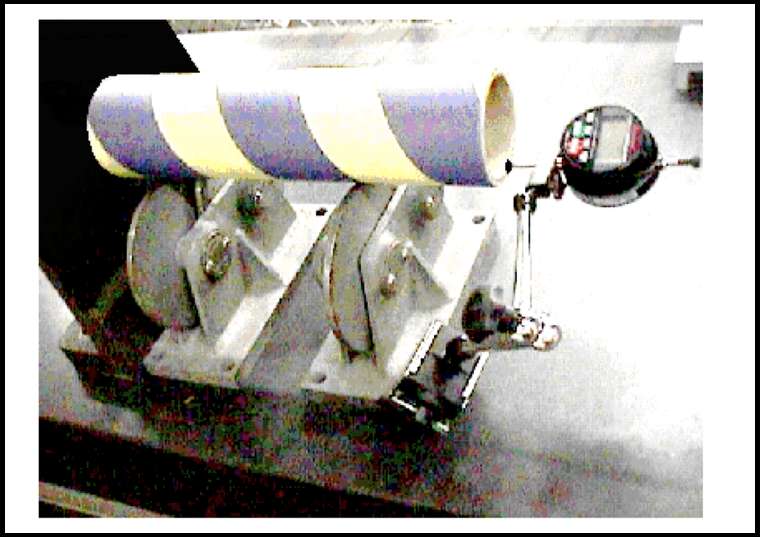

similar to the one I use to square

similar to the one I use to square

That's what I use as well. Thanks

A conventional arrow saw will not cut a square end (GG's pic), even by rotating it. The first end will be short one one side. The second end may be good or maybe twice as bad depending on rotational orientation. I could try to explain the "why" of it, but for those that doubt, you can set up a simple experiment to prove it using a table saw and a two foot piece of 1"X2" or wider. Or a two foot square, clamps and a pencil. If I get time today, maybe I can do a set up and take a few pics. Too bad I don't know how to post up videos. I've squared a lot of professionally, shop cut shafts. How much are they out? Not much, but if your anal enough to want as perfect as possible shafts then it's a good step to square them.

The Arrow Squaring Device (ASD, pic above) is a good affordable tool and an improvement over doing nothing. Do both ends.

If the shoulder is not square the broadhead point will be pulled toward the "short" side of the shaft, when it's tightened down. On the nock end the pressure will be exerted only on the "long" side of the shaft which could cause the arrow to flex differently. I think sometimes rotating nocks to bring an arrow back into the group helps because we might be "matching" a slightly off nock shoulder to a slightly off shaft shoulder.

There really should be a nock shoulder squaring device available too. Pretty easy to make.

Ultra said "It's a big pain, because you have to cut and square two ends. Basically double the time and effort.

You don't have 7-8 minutes?????????????? You spent more time here asking/responding if you should do it, than it would actually to take cut and square them.

I used to cut from both ends, figuring it may or may not help, but in any case wouldn't hurt and only took a minute or so more per shaft.

In recent years, have bought shafts with nocks already installed, and they're stuck in there pretty good! I pulled a few to cut them, but seemed like a lot more trouble for a procedure I wasn't sure was helping to start with, so I tried some with only cutting the other end, and found absolutely zero difference in group size or BH flight, so I abandoned the practice.

I also don't square the ends, and didn't even when I cut both ends. I cut the shafts using a thin cutoff wheel on one side of a bench grinder, holding the shaft by hand and turning it while finishing the cut to length while using VERY light pressure and touching the end to the side of the cutoff wheel. Takes a little practice, but I've done them that way for about fifty years now and still can't find a speck of evidence to support any need for squaring. I do use the CB inserts which have a long shank inside the shaft and fit the shaft ID with a "no-shake slip fit", that I'm sure keeps the alignment square. I have even checked that by intentionally cutting a few shafts ends with visibly un-square ends and they flew fine and impacted right with my others in the groups. Squaring devices may have some benefit to arrows with looser-fitting inserts, I never checked that out but see how it might.

Ugh...most arrow inserts with a raised collar that butts to the end of the shaft will automatically square themselves to the shaft, even if the cut isn't perfectly square. You could cut the shaft at a 45 degree angle and the front face of the insert would still be perpendicular to the shaft after it's inserted. The only time a slightly un-square cut presents a problem is after multiple shots into hard targets that causes the head and insert to bend in the direction of the short side of the cut.

That said, I routinely check the squareness of my cuts using a digital dial indicator mounted to my shaft straightening tool, similar to the setup above. Rarely are my cuts more than a few ten thousandths of an inch out of square. For perspective, that's about 50 times smaller than the thickness of a human hair. That's plenty square for my purposes. Small variations in fletching weight would have more impact on accuracy than that tiny bit of non-squareness.

Spine/fletch/broadhead indexing are the most important aspects of building accurate arrows, IMO. I've had the luxury of using a shooting machine to come that conclusion.

Matt

After reading these kinds of threads I get inferiority complexes and wonder how I kill anything at all. You guys do NOT want to know how I cut my arrows.

I cut both ends. From what I’ve read the best part of the arrow, spine and straightness, is measured over a 28” span a couple of inches in from each end.

Don’t worry Adam. I’m not building arrows quarter as good as I know how to either.

Holy GG, I'd be very interested to see some pics of the apparatus you use to measure .0002" axial run out on a 5/16" shaft!

I spent the last thirty years of my working life doing repairs that required fairly extreme precision measuring and machining. We would often get customers talking about "..a few thousands of an inch." on a job. We always said that precision costs money and more precise means more money. We would demonstrate by measuring a hair pulled from their head. Average thickness is about .006" and ranging from .0035' to .008". Those were pretty crude measurements for us, but nearly always impressed the customer that had never used a mic before or even a caliper.

But there's also no point in going overboard when it serves no or very little practical purpose.

Back when I was a very good competitive trad 3-D shooter, my "money arrow" was an aluminum Easton Gamegetter that had been straightened several times and looked like a frozen snake. Killed me when I lost it.

I appreciate the quest for perfection, but IMO unless you are shooting a super-fast, light setup for money, the extreme straightness obsession is overrated.

Rod,

You are correct, I misspoke. My dial indicator contraption read in the thousandths of an inch, not in ten thousandths. My mistake. I don't have it set up any more, mostly because I no longer think a perfectly square cut is absolutely necessary for an accurate arrow. My inserts have no visible gaps between their collar and the cuts, even under magnification, and they always spin true. That's good enough for me.

Matt

Yea I agree. Extreme strait ness might be overrated. But I’ve found spine tolerances to matter more for accuracy.

I get bored and tinker with my equipment in the off season. So I’ll do whatever to make myself more accurate.

Here is a group I’m pretty proud of. I shot the other week. 100 yards! I like to test things and practice far for real fun if it. If my equipment is shooting well at 100 it gives me confidence at 30 and 40 yards on a real hunt.

There’s not a poster on this thread that could tell the difference between a perfectly squared end and one that was done with a manual cut and some reasonable level care based on how they shot the two arrows in a blind test

People are debating a distinction with no difference and pure hypothetical that in practicality in the field is irrelevant

GG, how can you "routinely" do what you say you are doing with your arrows when you said on another thread that you've been using the same dozen arrows and broadheads for the past six years? If you haven't cut or fletched an arrow in 6 years, how can your info be relevant? Furthermore, anyone that suggests an arrow is square after cutting it on an arrow saw clearly has no clue. They might be close, but they aren't square.

From: Grey Ghost 28-Jan-20 I'm still using the same 6 broad-heads and a dozen shafts I bought 6 years ago, so I don't worry about their price much. Matt

Aluminum is the new Trad...... =D

I have to cut about five inches off of the shaft. I spin each arrow on an arrow spinner (yes, they still make and sell arrow spinners). I mark the end of the arrow the amount that I want to cut-off based on how well each end of the arrow spins. I always cut both ends and always square each end. I then re-spin the arrows and insert the nock on the straightest (best spinning) end. The cresting (middle sticker) on the arrows do not align and in many cases are on the point/broad head end of the arrow. I do spin my arrows once fletched and with broad heads. I try different broad heads on different arrows depending on how well they spin. This does not take that much time and once you're done, your done. I would recommend following this or similar process. I also weight all my arrows and arrow components (I don't enjoy this part), but my arrows are consistent. If you have never weighed or spun your arrows, especially when you get +/-.003 straightness or greater and +/- 2 gr. and greater in weight difference, you will almost always find arrows that are quite a bit different.

Just my two cents.

I do out of habit, shooting the older CarbonTechs...Although I don’t have anymore bare shafts to deal with now...We called it the watermelon cut!

Used to worry about all the floating for spine, indexing, squaring the ends, and on and on. It doesn't matter.

Used to group casings, bullet weight, seat according to the ogive with a comparator, and on and on. It doesn't matter either...

I was doing the double end cuts, squaring, checking for wobble and marking the spine but after robin hooding all the arrows I now just make sure my broadheads spin.